Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.

Hi! Simply click below and type your query.

Our experts will reply you very soon.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor, Importer |

| Accuracy | +- 0.25% Fso (h); +- 0.5% Fso (m) |

| Output | 0-10 Vdc |

| Thread | 1/2 - 20 Unf |

| Click to view more | |

Product Details

As a quality driven institution, we are committed to manufacturing, exporting and supplying of exclusive range of Melt Pressure Transducers that are widely used in variety of industries like food, medical, chemical, etc. Our team of quality controllers checks the lot of raw materials, prior to assembling of Melt Pressure Transducers. These transducers are available in two unique styles; buyers can acquire them as per their requirements. We provide customized solutions, at cost effective prices.

Details : Melt Pressure Sensors are utilized in a wide variety of industries, including polymer, food, medical, and chemical extrusion processing applications. Melt Pressure Sensors are available in two unique Styles. The CT style is the classic melt pressure sensor with a 6" rigid stem and 18" of flex capillary for optimum thermal isolation. The RT style offers only a 6" rigid stem. Both styles come standard with the 6-pin Bendix style bayonet connector, and a 1/2-20 UNF mounting thread. Our Melt Pressure Sensors are fully interchangeable with all other major brands Melt Pressure Transducer

Description : The Melt Pressure Transducer is ideal for general purpose Melt pressure applications. The unit features the industry standard 3.33 mV/Volt output and offers pin-to-pin compatibility with all competitors models utilizing the Bendix style 6 pin bayonet connector.The Melt Pressure Transducer comes standard with a 6" rigid stem, 18" of flexible capillary, and a 1/2-20 UNF thread for mounting in standard transducer mounting holes.Melt Pressure Transducers are measuring instruments that are subject to damage if mishandled, improperly installed

or dropped.

Features :

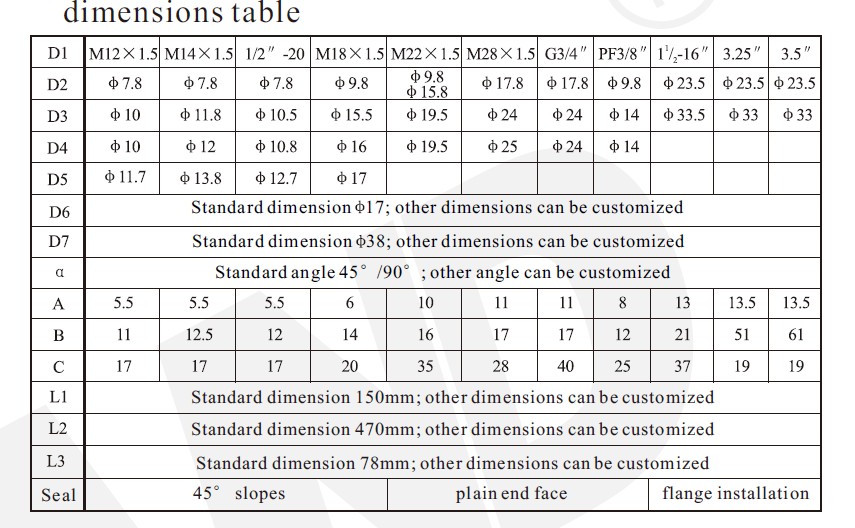

Dimensions Table

Melt Pressure Transducers - mV Outputs

| Industry | Maximum Media Temperature | Standard Output | Standard Pressure Ranges |

| Polymer Extrusion |

400oC (750oF) | 3.33 mV/V, 3.0 mV/V, 2.0 mV/V | 0-500 psi to 0-30,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |

| Food,Medical &ChemicalProcessing | 538oC (1,000oF) | 3.33 mV/V, 3.0mV/V, 2.0 mV/V | 0-500 psi to 0-10,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |

| Food,Medical &ChemicalProcessing | 315oC (617oF) | 3.33 mV/V, 3.0mV/V, 2.0 mV/V | 0-500 psi to 0-10,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |

Melt Pressure Transmitters - Amplified Outputs

| Industry | Maximum Media Temperature | Standard Output | Standard Pressure Ranges |

| Polymer Extrusion |

400oC (750oF) | 4-20 mA or0-10 Vdc | 0-500 psi to 0-30,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |

| Food,Medical &ChemicalProcessing | 538oC (1,000oF) | 4-20 mA or 0-10 Vdc | 0-500 psi to 0-10,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |

| Food,Medical &ChemicalProcessing | 315oC (617oF) | 4-20 mA or 0-10 Vdc | 0-500 psi to 0-10,000 psi, 0-100, 0-200,0-350, 0-700 Bar, 0-20, 0-35,0-40, 0-75 MPa |